Chemical gear pumps are trusted workhorses when it comes to precise fluid handling, particularly in demanding applications where corrosive, abrasive, or otherwise challenging liquids are involvedBut how do you ensure you’re choosing the right chemical gear pump for your specific needs? The material of the pump, along with its design, flow rate, and compatibility with your fluid properties, can make or break your operational success.

This guide will walk you through the essentials of chemical gear pumps, their unique value in handling corrosive fluids, and how to select the best one for your application.

Why Chemical Gear Pumps Are the Industry Standard

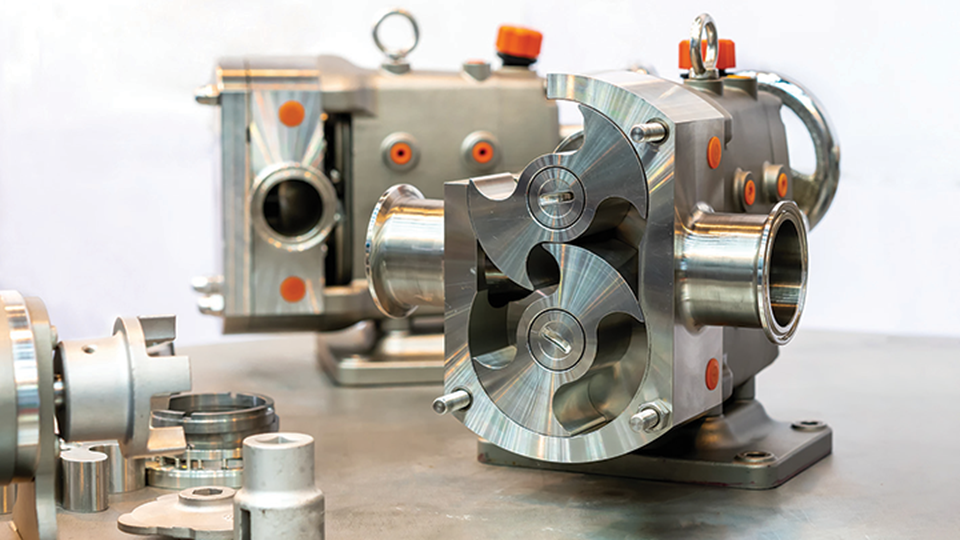

Chemical gear pumps are positive displacement pumps designed to handle high-viscosity fluids and maintain consistent flow, even under extreme operating conditionsThey are often used in industries like chemicals, petrochemicals, pharmaceuticals, and food processing because of their precision and reliability.

When dealing with corrosive fluids, the resilience of chemical gear pumps stands outTheir ability to deliver accuracy without compromising on durability makes them essential for applications where the chemical integrity of materials is critical.

Key Features of Gear Pumps

- Precision Metering: Gear pumps provide a steady, pulseless flow, making them ideal for processes requiring exact dosing or transfer rates.

- High-Pressure Capabilities: They can efficiently handle high-pressure applications without degradation in performance.

- Versatility: Chemical gear pumps handle a wide range of fluid viscosities, from thin solvents to thick resins.

Use Cases for Chemical Gear Pumps

- Producing high-purity pharmaceuticals or cosmetics

- Transferring acids, bases, or solvents in chemical plants

- Dispensing adhesives or lubricants in manufacturing

Given these applications, it’s clear that not all chemical gear pumps are created equalSelecting the right one means carefully considering the challenges posed by corrosive fluids.

The Importance of Material Selection in Chemical Gear Pumps

Corrosive fluids—like acids, bases, or harsh solvents—pose a unique challenge due to their highly reactive natureThe materials used in the pump must prevent degradation to maintain safety, efficiency, and longevity.

Materials Commonly Used in Chemical Gear Pumps

-

Stainless Steel (316 or Higher)

Stainless steel pumps are widely appreciated for their resistance to corrosion, durability, and affordabilityThey can handle fluids such as mild acids, organic chemicals, and petroleum-based liquids.

- Pros: Durable, cost-effective, suitable for most low- to moderate-corrosive fluids

- Cons: May not withstand highly concentrated acids or alkalis

-

Hastelloy

Hastelloy is a nickel-molybdenum alloy known for withstanding extremely corrosive chemicals such as hydrochloric acid or sulfuric acid.

- Pros: Exceptional corrosion resistance, ideal for highly aggressive fluids

- Cons: More expensive compared to stainless steel

-

Titanium

For handling extreme environments and exotic chemicals, titanium is the gold standardIts light weight and exceptional corrosion resistance make it indispensable in specialty applications.

- Pros: Ultra-light yet strong, resistant to marine environments

- Cons: High cost limits use to niche industries

-

Thermoplastics like PVDF (Polyvinylidene Fluoride)

Non-metallic pumps made from PVDF or other engineered plastics offer excellent corrosion resistance to both acids and bases.

- Pros: Lightweight, cost-effective, non-reactive to many chemical classes

- Cons: Limited mechanical strength for high-pressure operations

How to Match Material to Fluid Compatibility

Before selecting a material, it’s crucial to analyze the chemical resistance chart for your specific fluidCheck for reactions between the pump’s materials and your fluid to avoid unwanted wear, corrosion, or contaminationEngaging with material compatibility resources or consulting an engineer can ensure your selection is a perfect fit.

Other Factors to Consider for Your Chemical Gear Pump

Material is a top priority when handling corrosive fluids, but there are several other factors to consider to ensure optimal performance.

Flow Rate and Viscosity

Determine the flow rate and viscosity range of your fluid to select a pump that can handle these metrics without cavitation or wear issuesGear pumps excel at managing high-viscosity liquids, but the wrong selection can lead to inefficiencies or overloading.

Temperature Tolerance

The operating temperature of your fluid can affect the pump’s material integrityMetals like stainless steel and Hastelloy are suitable for high-temperature operations, whereas thermoplastics may not perform well above certain thresholds.

Seal Type

Corrosive fluids require reliable sealing mechanisms to ensure safety and prevent leaksOptions may include mechanical seals for better fluid containment or magnetic couplings for seal-less designs, which completely eliminate the possibility of leakage.

Maintenance Requirements

Pumps exposed to corrosive chemicals often require additional maintenance checks to ensure continued reliabilityChoose a pump that balances durability with ease of cleaning and repair.

Budget and ROI

While high-performance materials like titanium or Hastelloy may seem costly upfront, their ability to withstand corrosive environments often reduces long-term maintenance costs, downtime, and replacement needsInvesting in the right pump material can deliver significant ROI.

Best Practices for Handling Corrosive Fluids with Gear Pumps

- Flushing After Use: Prevent residue buildup by flushing the pump immediately after handling corrosive fluids.

- Routine Inspections: Regularly check for leaks, material degradation, and abnormal wear patterns.

- Use of Coatings: Applying protective coatings can enhance the durability of materials like stainless steel in moderately corrosive environments.

- Training Operators: Ensure staff is trained to handle both the pump and the corrosive fluids safely.

Achieving Operational Excellence

Careful material selection and regular maintenance make chemical gear pumps indispensable tools for industries dealing with corrosive chemicalsBy investing in the right pump, you ensure the safety, efficiency, and longevity of your equipment—allowing your operations to thrive.